Chemical Engineering Gate Yearwise

Chemical Eng. Gate 2024

Chemical Eng. Gate 2023

Chemical Eng. Gate 2022

Chemical Eng. Gate 2021

Chemical Eng. Gate 2020

Chemical Eng. Gate 2019

Chemical Eng. Gate 2018

Chemical Eng. Gate 2017

Chemical Eng. Gate 2016

Chemical Eng. Gate 2015

Chemical Eng. Gate 2014

Chemical Eng. Gate 2013

Chemical Eng. Gate 2012

Chemical Eng. Gate 2011

Chemical Eng. Gate 2010

Chemical Engineering Gate 2013 Questions with Answer

Ques 40 GATE 2013

All professors are researchers

Some scientists are professors

Which of the given conclusions is logically valid and is inferred from the above arguments:

Ques 41 GATE 2013

The effectiveness of a heat exchanger in the ε-NTU method is defined as

Ques 42 GATE 2013

In a pool boiling experiment, the following phenomena were observed.

P. Natural convection

Q. Film boiling

R. Transition boiling

S. Nucleate boiling

What was the CORRECT sequence of their occurrence?

Ques 43 GATE 2013

A hole of area 1 cm2 is opened on the surface of a large spherical cavity whose inside temperature is maintained at 727°C. The value of Stefan-Boltzmann constant is 5.67×10-8 W/m2-K4. Assuming black body radiation, the rate at which the energy is emitted (in W) by the cavity through the hole, up to 3 digits after the decimal point, is

Ques 44 GATE 2013

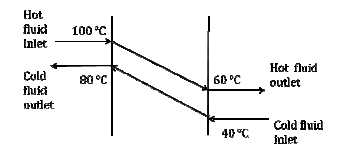

In a double pipe counter-current heat exchanger, the temperature profiles shown in the figure were observed. During operation, due to fouling inside the pipe, the heat transfer rate reduces to half of the original value. Assuming that the flow rates and the physical properties of the fluids do not change, the LMTD (in °C) in the new situation is

Ques 45 GATE 2013

Match the following.

Group 1

(P) Viscosity

(Q) Pressure

(R) Velocity

(S) Temperature

Group 2

(1) Pyrometer

(2) Hot wire anemometer

(3) Rheometer

(4) Piezoelectric element

Ques 46 GATE 2013

A unit gain 2nd order underdamped process has a period of oscillation 1 second and decay ratio 0.25. The transfer function of the process is

Ques 47 GATE 2013

A control valve, with a turndown ratio of 50, follows equal percentage characteristics. The flow rate of a liquid through the valve at 40% stem position is 1 m3/h. What will be the flow rate in m3/h at 50% stem position, if the pressure drop across the valve remains unchanged? (Up to 2 digits after the decimal point.)

Ques 48 GATE 2013

Consider the following transfer function

Gp(s)=5/(2s+1)4

(Note: The unit of the process time constant is in seconds.)

The crossover frequency (in rad/s) of the process is

Ques 49 GATE 2013

Consider the following transfer function

Gp(s)=5/(2s+1)4

(Note: The unit of the process time constant is in seconds.)

For the computation of Ziegler-Nichols settings, the ultimate period (in s/cycle) and the ultimate gain are

Ques 50 GATE 2013

A reverse osmosis unit treats feed water (F) containing fluoride and its output consists of a permeate stream (P) and a reject stream (R). Let CF CP, and CR denote the fluoride concentrations in the feed, permeate, and reject streams, respectively. Under steady state conditions, the volumetric flow rate of the reject is 60 % of the volumetric flow rate of the inlet stream, and CF=2 mg/L and CP=0.1 mg/L.

The value of CR in mg/L, up to one digit after the decimal point, is

Ques 51 GATE 2013

A reverse osmosis unit treats feed water (F) containing fluoride and its output consists of a permeate stream (P) and a reject stream (R). Let CF CP, and CR denote the fluoride concentrations in the feed, permeate, and reject streams, respectively. Under steady state conditions, the volumetric flow rate of the reject is 60 % of the volumetric flow rate of the inlet stream, and CF=2 mg/L and CP=0.1 mg/L.

A fraction f of the feed is bypassed and mixed with the permeate to obtain treated water having a fluoride concentration of 1 mg/L. Here also the flow rate of the reject stream is 60% of the flow rate entering the reverse osmosis unit (after the bypass). The value of f, up to 2 digits after the decimal point, is

Ques 52 GATE 2013

The packing of an existing absorption tower is replaced with a new type of packing. The height of the packing and the inlet conditions are maintained the same as before. Tests reveal that the number of transfer units is lower than before. This indicates that the tower with the new packing, when compared to that with the old packing, will

Total Unique Visitors